Surface Finish

SURFACE FINISH

Heat treatment

Heat treatment is a kind of metal thermal processing technology. The material gradually achieves the expected structure and performance through heating, heat preservation and cooling in the solid state. Metal heat treatment processes can be roughly divided into three categories: overall heat treatment, surface heat treatment and chemical heat treatment. In general, the shape of the parts and the overall chemical composition are not changed. By changing the internal microstructure of the parts, or changing the chemical composition of the surface of the parts, the use performance of the parts can be improved. Its characteristic is to improve the internal quality of the parts, which is usually not visible.

Oxidized Black and Black Anodized

Oxidized Black treatment is a common method of chemical surface treatment. The principle is to produce an oxide film on the metal surface to isolate the air and achieve the purpose of rust prevention. Blackening treatment can be used when the appearance requirements are not high. The surface blackening treatment of steel parts is also called blued. Anodizing is the electrochemical oxidation of metals or alloys. Aluminum and its alloys form a layer of oxide film on aluminum products (anode) under the action of applied current under corresponding electrolyte and specific process conditions. If anodizing is not specified, it usually refers to sulfuric acid anodizing.

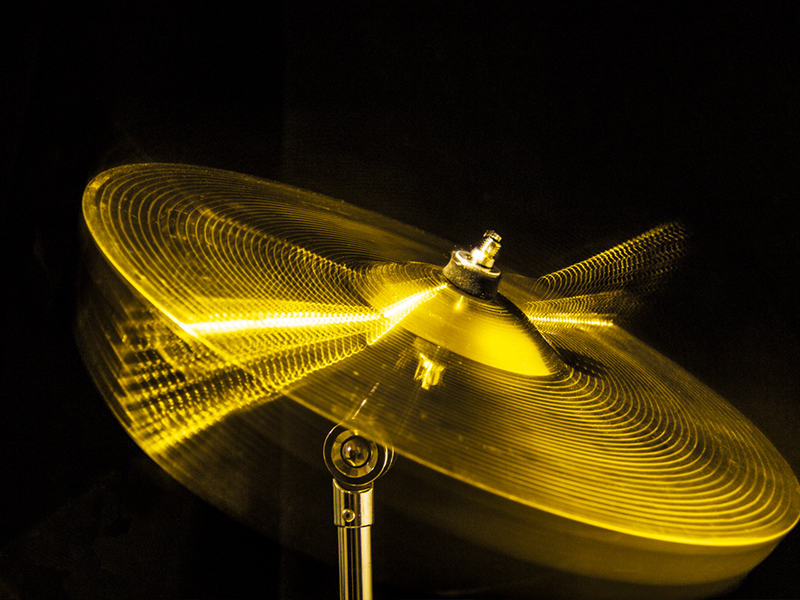

Polishing

Polishing refers to the use of mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. It is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

Nitriding

Nitriding treatment refers to a chemical heat treatment process in which nitrogen atoms infiltrate the surface of the workpiece in a certain medium at a certain temperature. Nitrided products have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. Standard nitrided steel containing aluminum can obtain a high hardness and high wear-resistant surface layer after nitriding, but its hardened layer is very brittle. On the contrary, chromium-containing low-alloy steel has lower hardness, but the hardened layer is more tough, and its surface has considerable wear resistance and corrosion resistance.

-

Phone

-

E-mail

-

Top