Good Quality Cnc Milling And Turning - CNC Milling – QY Precision

Good Quality Cnc Milling And Turning - CNC Milling – QY Precision Detail:

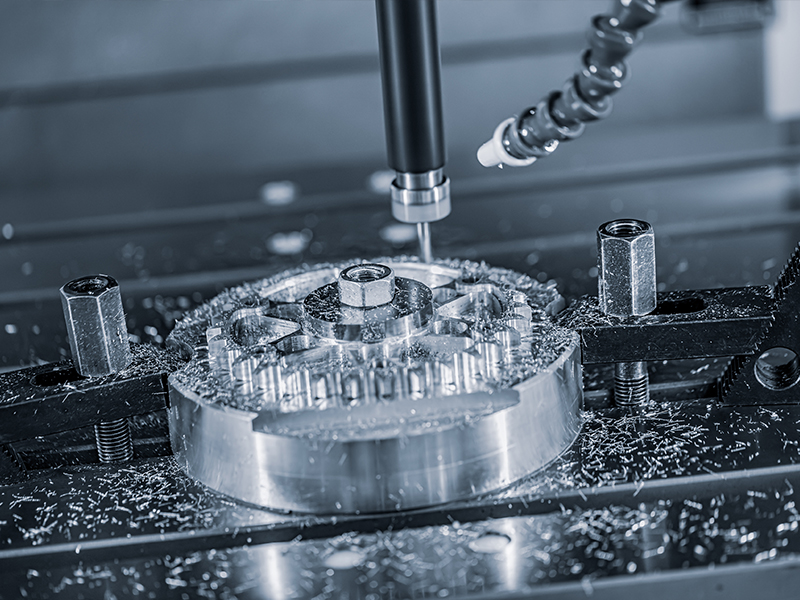

CNC MILLING

What is CNC milling?

CNC milling processing is a high-tech processing method of precision hardware parts. Various types of materials can be processed, such as 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, acrylic, Teflon, POM rods and other metal and plastic raw materials. Processed into a complex structure of square and round parts. CNC milling machines are divided into two types: without tool magazine and with tool magazine. Among them, the CNC milling machine with a tool magazine is also called a machining center. QY Precision can meet your different processing needs and guaranty the delivery. Welcome contact us and send drawings or sample to get free quotation.

What’s the feature?

The processing surface shape of a milling machine is generally composed of straight lines, arcs or other curves. The operator of the milling machine constantly changes the relative position between the cutter and the workpiece according to the requirements of the drawing, and then matches the selected milling cutter speed to cutting the workpiece, and can process various parts of different shapes.

CNC milling machine processing is to divide the movement coordinates of the cutter and the workpiece into the smallest unit quantity, that is the smallest displacement. According to the requirements of the workpiece program, the numerical control system moves each coordinate by several minimum displacements, so as to realize the relative movement of the tool and the workpiece to complete the processing of the parts.

CNC milling machine processing is to divide the movement coordinates of the cutter and the workpiece into the smallest unit quantity, that is the smallest displacement. According to the requirements of the workpiece program, the numerical control system moves each coordinate by several minimum displacements, so as to realize the relative movement of the tool and the workpiece to complete the processing of the parts.

4. The machining accuracy is high, and the quality is stable and reliable. The pulse equivalent of the numerical control device is generally 0.001mm, and the high-precision numerical control system can reach 0.1μm. In addition, the numerical control processing also avoids the operating errors of the operator;

5. The high degree of production automation can reduce the labor intensity of the operator. Conducive to the automation of production management;

6. The production efficiency is high. The CNC milling generally does not need special process equipment such as special fixtures. When replacing the workpiece, it only needs to call the processing program, clamping tool and adjustment tool data stored in the CNC device, thus greatly shortening the production cycle. Secondly, the CNC milling machine has the functions of milling machine, boring machine and drilling machine, which makes the process highly concentrated and greatly improves the production efficiency. In addition, the spindle speed and feed speed of the CNC milling machine are continuously variable, so it is helpful to choose the best cutting amount.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Good Quality Cnc Milling And Turning - CNC Milling – QY Precision , The product will supply to all over the world, such as: Belize, United States, Pakistan, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

-

Phone

-

E-mail

-

Top