China wholesale Metal Stamping - Stamping Processing – QY Precision

China wholesale Metal Stamping - Stamping Processing – QY Precision Detail:

STAMPING PROCESS

What is Stamping processing?

Stamping process is a metal processing method, which is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet to cause plastic deformation or separation of the sheet to obtain a certain shape, size and performance. Parts (stamped parts).

The stamping process occupies an important position in the automobile body manufacturing process, especially the large-scale covering parts of the automobile body. Because most of the large-scale covering parts of the automobile body are complicated in shape, large in structure, and some are spatially curved, and the surface quality requirements are high, the stamping process is used to The production of these parts is unmatched by other processing methods.

Stamping is a method of metal cold deformation processing. Therefore, it is called cold stamping or sheet metal stamping, or stamping for short.Sheet material, die and equipment are the three elements of stamping processing.

Of the world’s steel, 60 to 70% are plates, most of which are stamped into finished products. The car body, chassis, fuel tank, radiator fins, boiler drums, container shells, motors, electrical iron core silicon steel sheets, etc. are all stamped and processed. There are also a large number of stamping parts in products such as instruments, household appliances, bicycles, office machinery, and living utensils.

Compared with castings and forgings, stamping parts have the characteristics of thinness, uniformity, lightness and strength. Stamping can produce parts with stiffeners, ribs, undulations or flanges that are difficult to manufacture by other methods to improve their rigidity. Due to the use of precision molds, the accuracy of the parts can reach the micron level, and the repeatability is high, the specifications are consistent.

Main Application

Stamping processing has a wide range of applications in various fields. For example, in aerospace, aviation, military industry, machinery, agricultural machinery, electronics, information, railways, post and telecommunications, transportation, chemicals, medical appliances, household appliances and light industry, there are stamping processes. Not only used in the entire industry, but every individual has direct contact with stamping products. There are many large, medium and small stamping parts on airplanes, trains, automobiles, and tractors. The car body, frame, rim and other parts are all stamped out. According to relevant survey statistics, 80% of bicycles, sewing machines, and watches are stamped parts; 90% of TV sets, tape recorders, and cameras are stamped parts; there are also food metal tank shells, reinforced boilers, enamel basins and stainless steel tableware, all of which are stamped parts.

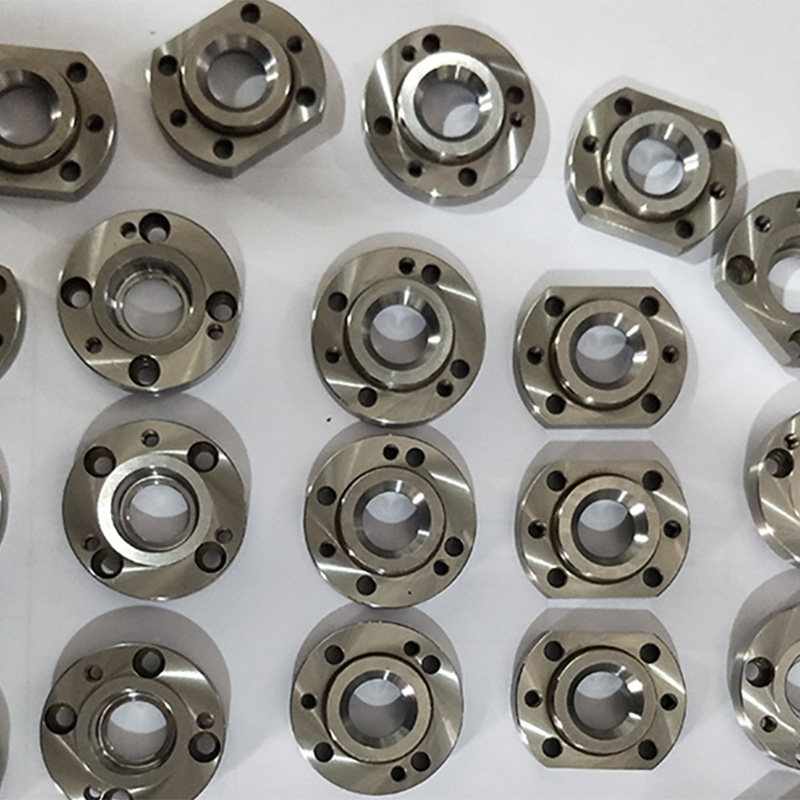

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for China wholesale Metal Stamping - Stamping Processing – QY Precision , The product will supply to all over the world, such as: Jersey, Czech Republic, Barcelona, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Phone

-

E-mail

-

Top