China wholesale Cnc Turning Part - CNC Turning – QY Precision

China wholesale Cnc Turning Part - CNC Turning – QY Precision Detail:

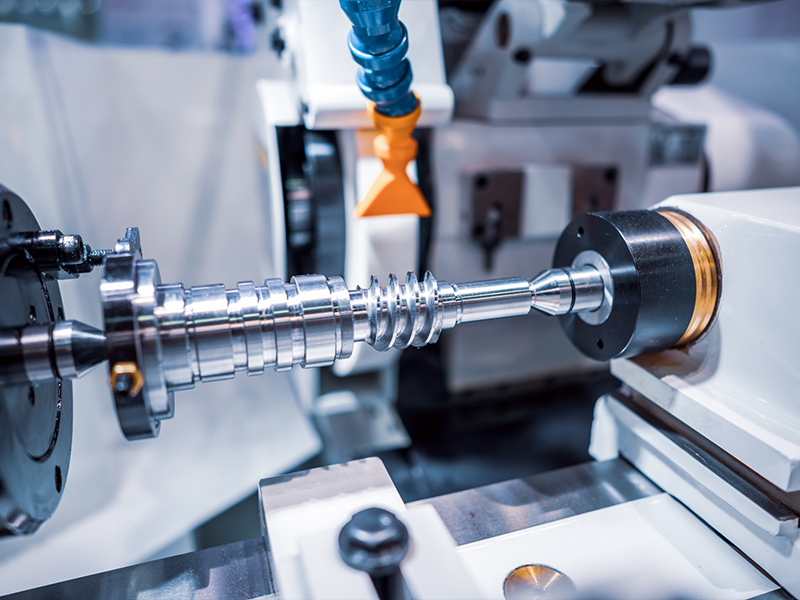

CNC TURNING

WHAT IS CNC TURNING ?

CNC turning generally uses general-purpose or special-purpose computers to achieve digital program control, so CNC is also called Computerized Numerical Control (CNC) for short.

CNC lathe processing is mainly used for the cutting of inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer curved surfaces, cylinders, and conical threads. It can also perform grooving, drilling and boring etc.

Traditional mechanical processing is performed by manual operation of ordinary machine tools. During processing, the mechanical tool is shaken by hand to cut metal, and the accuracy of the product is measured by tools such as eyes and calipers. Compared with traditional lathes, CNC lathes are more suitable for turning revolving parts with the following requirements and characteristics:

(1) Parts with high precision requirements

Due to the high rigidity of the CNC lathe, the high precision of manufacturing and tool setting, and the convenient and accurate manual compensation or even automatic compensation, it can process parts with high dimensional accuracy. In some occasions, you can use a car instead of grinding. In addition, because the tool movement in CNC turning is realized by high-precision interpolation and servo drive, coupled with the rigidity of the machine tool and high manufacturing accuracy, it can process the parts with high requirements on the straightness, roundness, and cylindricity of the generatrix.

(2) Rotary parts with good surface roughness

CNC lathes can machine parts with small surface roughness, not only because of the rigidity and high manufacturing accuracy of the machine tool, but also because of its constant linear speed cutting function. In the case that the material, the amount of fine turning and the tool have been determined, the surface roughness depends on the feed speed and cutting speed. Using the constant linear speed cutting function of the CNC lathe, you can choose the best linear speed to cut the end face, so that the cut roughness is small and consistent. CNC lathes are also suitable for turning parts with different surface roughness requirements. The parts with small roughness can be achieved by reducing the feed speed, which is not possible on traditional lathes.

(3) Parts with complex contour shapes

The CNC lathe has the function of arc interpolation, so you can directly use the arc command to process the arc contour. CNC lathes can also process contour revolving parts composed of arbitrary plane curves. It can process curves described by equations as well as list curves. If turning cylindrical parts and conical parts can use traditional lathes or CNC lathes, then turning complex rotating parts can only use CNC lathes.

What are the characteristics of CNC turning?

1. In the process of CNC lathe processing, the workpiece rotates around a fixed axis, which can better ensure the coaxiality between the processing surfaces and the accuracy of each processing surface.

2. The machining process of the CNC turning is continuous. But if the surface of the workpiece appears discontinuous then Vibration occurs.

3. The materials processed by some precision mechanical parts have low hardness and good plasticity. It is difficult to obtain a smooth surface with other machining methods, but it is easier to reach a smooth surface with CNC lathe processing for finishing.

4. The Magazine used in CNC Turning is the simplest one in all mechanical processing methods. It is very simple and convenient whether it is manufacturing, sharpening or installation, and can better meet the processing requirements of the workpiece.

CNC lathe processing has its own characteristics different from other mechanical processing, so it can occupy a place in many mainstream mechanical processing methods.

Welcome send your drawings for quotation, QY Precision is your best partner.

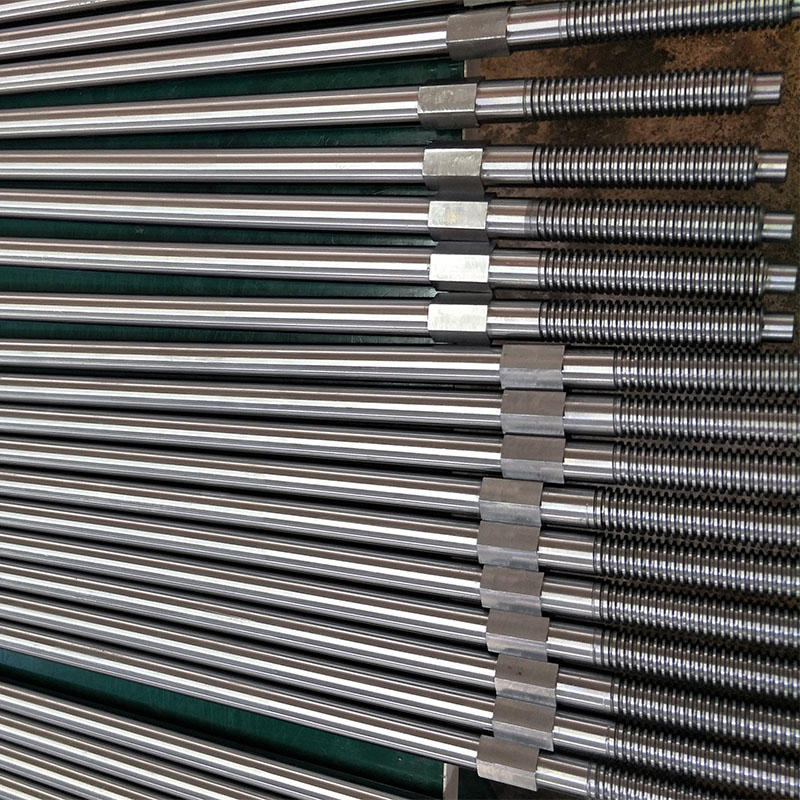

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for China wholesale Cnc Turning Part - CNC Turning – QY Precision , The product will supply to all over the world, such as: Turkey, Hyderabad, Guyana, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

-

Phone

-

E-mail

-

Top