2021 wholesale price Sheet Metal Stamping Process - Stamping Processing – QY Precision

2021 wholesale price Sheet Metal Stamping Process - Stamping Processing – QY Precision Detail:

STAMPING PROCESS

What is Stamping processing?

Stamping process is a metal processing method, which is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet to cause plastic deformation or separation of the sheet to obtain a certain shape, size and performance. Parts (stamped parts).

The stamping process occupies an important position in the automobile body manufacturing process, especially the large-scale covering parts of the automobile body. Because most of the large-scale covering parts of the automobile body are complicated in shape, large in structure, and some are spatially curved, and the surface quality requirements are high, the stamping process is used to The production of these parts is unmatched by other processing methods.

Stamping is a method of metal cold deformation processing. Therefore, it is called cold stamping or sheet metal stamping, or stamping for short.Sheet material, die and equipment are the three elements of stamping processing.

Of the world’s steel, 60 to 70% are plates, most of which are stamped into finished products. The car body, chassis, fuel tank, radiator fins, boiler drums, container shells, motors, electrical iron core silicon steel sheets, etc. are all stamped and processed. There are also a large number of stamping parts in products such as instruments, household appliances, bicycles, office machinery, and living utensils.

Compared with castings and forgings, stamping parts have the characteristics of thinness, uniformity, lightness and strength. Stamping can produce parts with stiffeners, ribs, undulations or flanges that are difficult to manufacture by other methods to improve their rigidity. Due to the use of precision molds, the accuracy of the parts can reach the micron level, and the repeatability is high, the specifications are consistent.

Main Application

Stamping processing has a wide range of applications in various fields. For example, in aerospace, aviation, military industry, machinery, agricultural machinery, electronics, information, railways, post and telecommunications, transportation, chemicals, medical appliances, household appliances and light industry, there are stamping processes. Not only used in the entire industry, but every individual has direct contact with stamping products. There are many large, medium and small stamping parts on airplanes, trains, automobiles, and tractors. The car body, frame, rim and other parts are all stamped out. According to relevant survey statistics, 80% of bicycles, sewing machines, and watches are stamped parts; 90% of TV sets, tape recorders, and cameras are stamped parts; there are also food metal tank shells, reinforced boilers, enamel basins and stainless steel tableware, all of which are stamped parts.

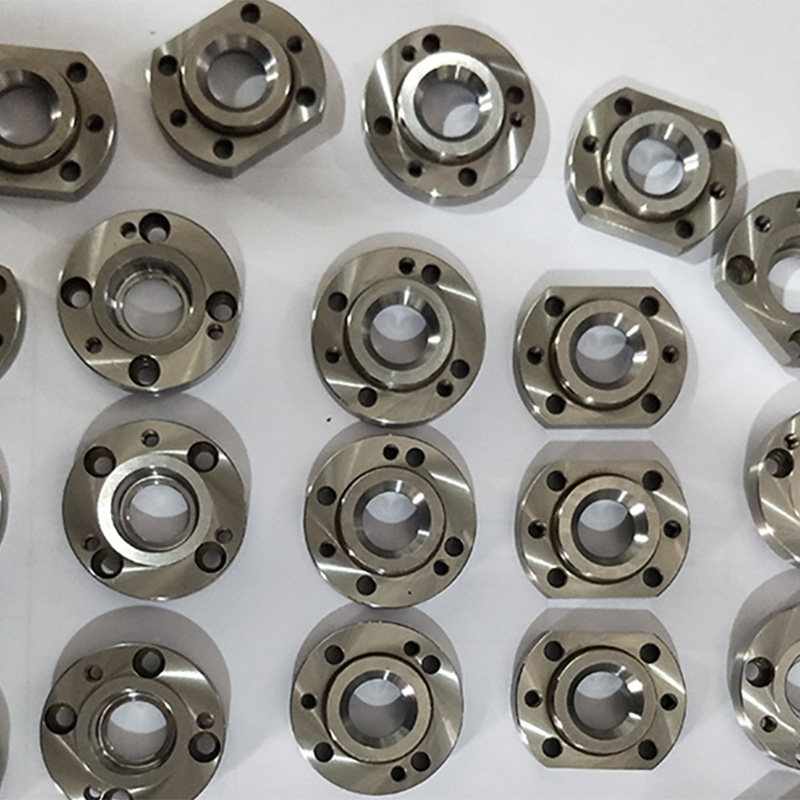

Product detail pictures:

Related Product Guide:

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for 2021 wholesale price Sheet Metal Stamping Process - Stamping Processing – QY Precision , The product will supply to all over the world, such as: Finland, Thailand, Vietnam, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

-

Phone

-

E-mail

-

Top